Long term protection for wooden windows and doors

Water coating testing

We are dedicated to offering products with the longest guarantees in the industry. The difficulty lies in the fact that we are endeavouring to give guarantees of a decade or longer, but obviously cannot do a physical test of the products for this length of time. As such, we have to be a little creative in finding testing techniques that give us confidence that the products will last but over a much shorter testing period. This has been done through Q-UV testing.

Our water based paint coatings are guaranteed for 10-years with zero maintenance required during that period. While we have been using water based coatings for a number of years and are confident of their general performance over 12 years (David’s blog), when we changed our supplier in 2013 we needed to be convinced that the product would live up to the promises. We prepared a number of samples of timber and sent these out to Venice, where our new supplier is based. They applied the coatings to our agreed process and specification, and those samples then underwent Q-UV testing over the course of 4 months.

Q-UV testing is a process of putting the samples into an enclosed environment where they can be subjected to concentrated cycles of UV exposure, heat and moisture to replicate the equivalent of a standard day but in a much shorter time. Over the course of 4-months, these cycles form the equivalent of 10-years of regular service. It is worth mentioning that the standards for these tests (i.e. the ferocity of each element in the cycle) may vary dependant on the location being simulated.

The BWF (British Woodworking Federation) have undertaken a project called Servowood, which is a true test of products and coatings over 18-years. They have then done Q-UV testing on similar samples and compared the results; this has proved that the Q-UV testing is accurate as a true test of performance. The BWF minimum recommendation for water-based paint build-up is 140 microns, we apply our coatings to a total thickness of 210-250 microns, which demonstrates the potential improvement in lifespan.

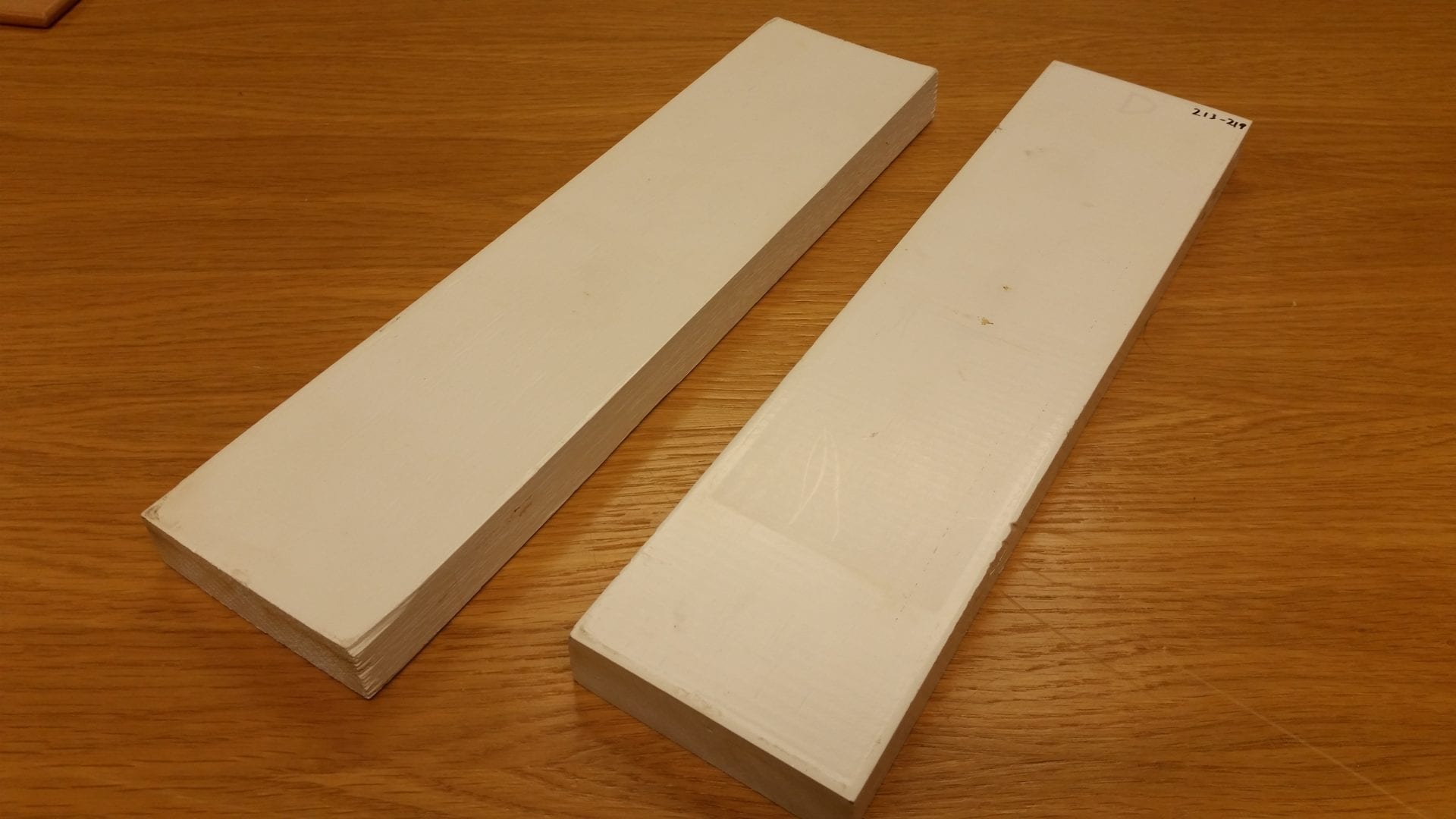

The samples that we have run through the Q-UV test can be seen in the attached photographs and we have kept the physical samples at our offices. Where the coating has been exposed, there is some low level erosion of the coating and also a loss of sheen. This is relatively minor and the samples need to be reviewed in the correct light to enable this to be seen. It is also worth noting that the Italian simulator that we used for our samples will have much higher UV exposure than a UK simulator would, due simply to the climate of the two regions. As such, we estimate that these samples have seen the equivalent of 12-15 years of regular UK service.

This testing proves that the coating on our products will easily last the initial 10-years until recoating and for this reason we are happy to offer a full, no maintenance guarantee for 10-years. The recoating cycles are quick and easy, and are only required every subsequent 7-years. If you are still concerned about maintenance, then I would suggest looking at our TimbaCare programme, which passes all servicing and maintenance requirements back to Gowercroft and is the only truly worry-free window and door solution on the entire market and across all substrates.

We are also currently in the process of Q-UV testing samples to allow us to offer a 15-year no maintenance guarantee on coatings when applied to Accoya. This is another massive step above and beyond what anyone else can offer in our whole industry.

If you have any questions about this process or would like more information, then we would be glad to help, please just give us a call in the office or email us through the contact us page on this website.