Are you seeking the most energy efficient windows possible? Then your windows need low u-values.

A whopping 85% of us globally report being impacted by climate change. And it’s not just homeowners aiming for carbon neutral either. The UK government has also committed to reducing greenhouse gas emissions by 100% by 2050.

Given the context, it’s not surprising that it is now required by UK law that your window and door manufacturer shares calculated U-values on your new units. So what is a U-value?

What is a U-value

U-values are a measure of thermal performance. The lower the U-value, the better the material is at keeping heat in. This is especially important for windows.

A window with a low U-value is great because it helps keep your building warm and saves you money on heating bills.

What is the Required U-value for Window Building Regulations?

| Window or Door Type | For New Builds | For New Elements in Existing Dwellings | For Existing Elements in Existing Dwellings |

|---|---|---|---|

| Windows | 1.2 W/m²K | 1.4 W/m²K | 1.6 W/m²K |

| Glazed Doors | 1.2 W/m²K | 1.4 W/m²K | 1.8 W/m²K |

| Solid Doors | 1.0 W/m²K | 1.2 W/m²K | 1.8 W/m²K |

This table reflects the updates from Part L 2024, which aim to further enhance energy efficiency and reduce heat loss through building elements.

This does not apply to certain (typically historic) housing authorities, however Historic England’s Advice Note 18 (2024) emphasises the importance of updating historic homes for carbon efficiency.

Typical U-Values Table:

| Window Type | Cavity Width | Coating | Cavity Fill | U-Value (W/m²K) |

|---|---|---|---|---|

| Single glazed window | N/A | None | None | 5.6 |

| Double glazed window, with standard air cavity | 12mm-16mm | Clear | Air | 2.8 |

| Double glazed window, with argon-filled cavity | 12mm-16mm | Clear | Argon (90% fill) | 2.6 |

| Double glazed window (Low E glass), with standard air cavity | 12mm-16mm | Hardcoat Low-E | Air | 1.8 |

| Double glazed window (Low E glass), with argon-filled cavity | 12mm-16mm | Hardcoat Low-E | Argon (90% fill) | 1.5 |

| Triple glazed window (Low E glass), with argon-filled cavity | 12mm-16mm | Hardcoat Low-E | Argon (90% fill) | 0.8 – 1.0 |

| LandVac vacuum-glazed window | 0.1mm | None (vacuum cavity) | Vacuum (0.1mm gap) | 0.4 |

This is based on the glass only. Glass units are always measured from the centre of the pane.

Our argon filled double and triple glazed units are also better than “typical” as we have worked hard to find the lowest u-values available:

Double Glazed: 1.0 W/m²K

Triple Glazed: 0.5 W/m²K

Why are glazing unit u-values measured from the centre of the pane?

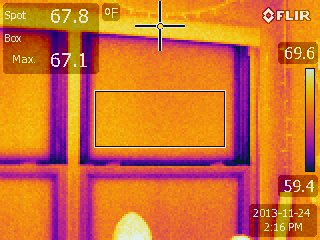

The centre of the pane is the most consistent place to measure thermal performance from. If you were to measure closer to the edges, the results could be less accurate due to heat loss at the window’s borders, where materials like spacers and frames conduct more heat. This edge area, known as a thermal bridge, doesn’t reflect the true insulating ability of the glass itself.

How is the U-Value of a Window Measured?

When it comes to the thermal insulation of windows, you need to measure more than just the glass.

To give an accurate measure of thermal conductivity, you must account for:

- Frame Material:

Different frame materials, such as timber, uPVC, or aluminium, have varying thermal performances. Timber and uPVC generally provide better insulation than aluminium, leading to lower U-values. - Spacer Bars:

The type of spacer bars used between glass panes can impact the overall U-value. Warm-edge spacers reduce heat loss more effectively than traditional metal spacers, improving thermal efficiency. - Frame Design and Size:

The size and design of the window can impact the U-value. Larger windows with more glass and less frame tend to have lower U-values, as glass typically insulates better than the frame. - Sealing and Fitting:

A well-sealed window is essential for minimising air leaks. Poorly sealed or incorrectly fitted windows create air gaps that reduce energy efficiency and increase the U-value. - Installation Quality:

Proper installation is critical for achieving optimal thermal performance. If windows are not fitted correctly, with gaps or improper alignment, the U-value will increase due to higher heat loss.

Why Should You Hold Your Window Manufacturer Accountable for U Values?

The British Woodworking Federation (BWF) have issued this statement, highlighting ongoing issues in the industry.:

“We hear that many window manufacturers are still not meeting their obligation to demonstrate the thermal performance of their windows and external door-sets and may not be achieving the necessary levels.”

“This is seen as a competitive advantage as poorer thermal performance can mean lower costs but a customer would be accepting work which did not comply with the Building Regulations and a manufacturer would be supplying a product which was not fit for purpose.”

If you do not choose windows with clear whole-unit U-values, you could be left with products that don’t meet energy efficiency expectations or building regulations.

While the centre-pane U-value might look impressive, it’s the performance of the entire unit, including the frame and spacers, that truly determines how well your windows will insulate your home. Without this transparency, you risk:

- Higher energy bills, as poor overall insulation can lead to heat loss.

- Inconsistent indoor temperatures, resulting in uncomfortable drafts or cold spots.

- Non-compliance with building regulations, which could lead to fines or the need for costly replacements.

- Decreased long-term performance, reducing the lifespan of your windows.

- Lower property value, as energy-efficient windows are an important selling point in today’s market.

Always ensure you’re provided with the full U-value for peace of mind and optimal performance.

U-Values are only one of many important considerations when choosing the right windows and doors. See our blog “9 Questions to ask your joiner about windows and doors” to find out what else to look out for.

Why is Gowercroft Joinery is the Best Choice for Low U-Value Windows and Doors?

At Gowercroft Joinery, we go well beyond the minimum requirements for U-Values.

In fact, our whole units significantly out-performs the government regulations:

Our whole-unit U-values, calculated using the EN1007 mandated standard sizes, are as follows:

- Classic Range: 1.2 W/m²K

- Heritage Range: 1.1 W/m²K

- Frontier Range: 0.9 W/m²K

These values reflect the average performance for each range. For your specific project, we provide tailored U-value calculations based on the exact sizes and specifications of your windows and doors, ensuring transparency and accuracy in every quotation.

Our quotes also accurately detail the whole window U-values of each individual unit.

To achieve these outstanding thermal performance standards, we employ the following key measures:

- Innovative Timber Choice: We use only the best timbers, including Accoya and engineered Red Grandis, which are selected for their long-term durability and thermal properties.

- Thoughtful Design: Our windows and doors are meticulously designed with narrow sightlines and optimised profiles to minimise heat loss while maintaining aesthetic appeal.

- Glazing Options: We use double glazing with low-e glass, argon-filled cavities, or vacuum glazing to deliver exceptional insulation.

- Warm-Edge Spacer Bars: We incorporate warm-edge spacer bars between glass panes to reduce heat loss, improve insulation, and enhance the overall thermal efficiency of our windows and doors.

- Wet Glazed and Internally Beaded as Standard: This ensures an airtight, long-lasting seal that enhances thermal efficiency and prevents moisture ingress.

- Careful Construction: Every product is assembled with precision to ensure high-quality craftsmanship that maximises insulation.

- Quality Gaskets: We use superior gaskets that ensure a perfect seal, further reducing heat loss and improving overall performance.

Want to know more? Contact us today to discuss how our products can enhance the thermal efficiency of your project.